We help people repair plastic

Welding a Broken Bumper Slot

Because of the strength provided by the nitrogen welding system, you can make strong repairs even when you don't have a lot of surface area on which to weld. A perfect example is the slots on the edge of the bumper where the bumper snaps into the quarter panel, like on a Honda bumper. These often seem to break out when the bumper is removed. There's not enough surface area to make a good repair with either a two-part system or with the FiberFlex. Here's how you fix a torn-out bumper slot.

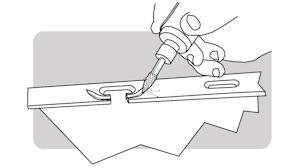

V-groove or taper the edges. Depending on the design of the flange, you can use the -01 profile round rod or the -07 profile narrow ribbon. The round rod needs to be used on bumpers where the flange is contoured around the slots. For straight flanges, like the one shown here, you can use the -07 ribbon since it doesn’t have to curve. In either case, use a 6121-T or 6125 die grinder bit to grind a channel into the bumper at least 1/2 inch (1.3 cm) long on both sides of the broken slot. Taper the plastic down almost to a point at the broken-out area. Remove any paint in the immediate area with sandpaper

Apply tape to support rod during weld. Use the 6481-1 or 6485 aluminum body tape underneath the hole to support the melted plastic welding rod. You can also clamp a strip of sheet metal or wood along the edge if that works better.

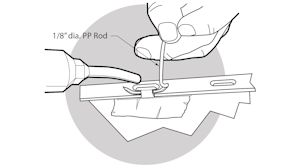

Weld across the gap. Use the R02-01 1/8 inch (3 mm) diameter polypropylene welding rod. Starting on one side, preheat the bumper and the end of the welding rod at the start of the prepared v-groove. When both plastics are preheated, touch the end of the rod down to the bumper and apply downward pressure to fold the rod toward the torch. When you get to the gap, continue heating the rod just as if you were melting to the bumper. Continue at the same pace, spanning across the gap and picking up the process on the other side. Continue welding until you reach the end of the prepared v-groove, at which point focus the hot nitrogen on the rod and twist the rod to break it.

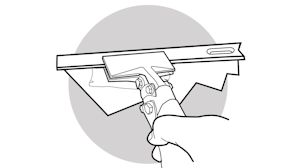

Heat until rod turns clear then compress with a hand seamer. If you're using our white polypropylene rod, you can see that it turns clear when it gets to the proper melting temperature. Heat up the ribbon you just laid down with the nitrogen welder until it all turns clear. (If you’re using the black rod, heat it until it all turns glossy black). Immediately use the 6145 hand seamer to gently press the melted ribbon down into the plastic. This also aligns the repaired section with the rest of the bumper. If necessary, weld another pass to build up the plastic's thickness.

Restore slot dimensions. Let the weld cool and remove the tape or metal support. Restore the original slot dimensions using either a rotary tool with a 6120 or 6123 straight burr, an airless plastic welder, or a utility knife. This is easier to do when using the white rod as you can see the underlying plastic’s original profile.

Weld opposite side. For maximum strength, repeat the welding process on the opposite side. Usually the tape or metal support is not needed, but it can make the process easier. After welding, press the repaired area flat and straight again using the hand seamer.

Restore slot dimensions and finish repair. After letting the weld cool, restore the final dimensions of the slot and bumper edge using a rotary tool, airless welder, or knife. Finish sand the outer surface with 180 then 320 grit paper to prepare it for paint.

welding plastic machine polyvance plastic welder parts urethane bumpers polycarbonate welding strips abs welding wire

Products Suggestions